General Information de las juntas

There are basically three categories of gasket: non-metallic, semi-metallic and metallic. The mechanical characteristics and the performance of a gasket can vary greatly depending on the material chosen to manufacture it. To make the right choice of gasket, the following should be calculated:

- Temperature

- Pressure

- Corrosive environment or agents that will attack the gasket

NON-METALLIC

These gaskets are normally used to work under low pressure in general or chemically corrosive environments. Examples include compressed cardboard gaskets, rubber gaskets, PTFE gaskets and graphite gaskets.

SEMI-METALLIC

These gaskets combine metallic and non-metallic materials. The metal makes them hard and resilient. They are recommended for high and low temperature and pressure environments. Examples include spiral wound gaskets and jacketed gaskets.

METALLIC GASKETS

These gaskets are made of a metal or a combination of metals in various shapes and sizes. They are recommended for high temperatures and pressures.

For further information about materials and sizes see the Download section

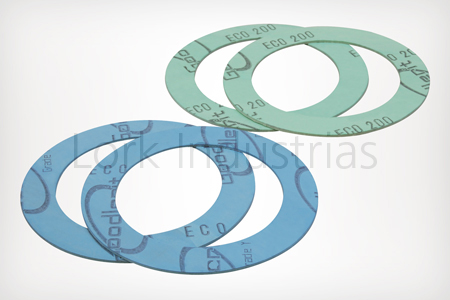

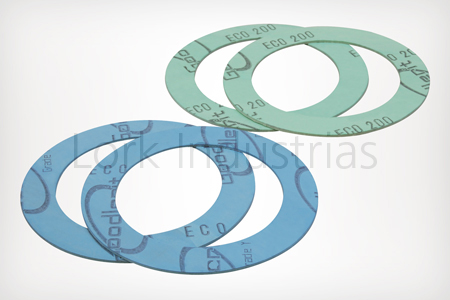

ECO 200

Non-asbestos compressed jointing sheet made of Aramid Fiber, Mineral Fiber, High Quality NBR & Organic Fibre. Colour: green. Max. temp: 350 �C.

ECO GF

Non-asbestos compressed jointing sheet made of Aramid Fiber, Mineral Fiber, High Quality NBR & Organic Fibre. With Graphite impregnation on both sides. Colour: anthracite. Max. temp: 350 �C.

ECO U

Non-asbestos compressed jointing sheet made of Aramid Fiber, Mineral Fiber and High Quality NBR.Colour: blue. Max. temp: 400 �C

ECO GFM

Non-asbestos compressed jointing sheet made of Aramid Fibre, Mineral Fibre, High Quality NBR & wire reinforced. With Graphite impregnation on both sides. Colour: anthracite. Max. temp: 500 �C.

These gaskets can be manufactured in compliance with Standards DIN 2690, DIN 2691 and B 16.21 for raised-face and flat-face flanges. We have a large stock of standard gaskets for immediate delivery.

For further information about materials and sizes see the Download section

PTFE

We choose PTFE to manufacture gaskets whenever they are needed to withstand extremely corrosive environments, as PTFE is practically chemically inert. It is only attacked by alkaline metals and certain fluoride compounds at high temperatures. However, the use of PTFE as a sealing material also has certain limitations as it has a very low friction coefficient. To overcome this problem, PTFE + fibreglass is often used. Temp: -200+260 �C

Polyamide

Polyamide has very good mechanical properties and high resistance to abrasion, rubbing and impacts. It is also recommended for use with machine oils but is not suitable for use in contact with acids. Temp: -80 +120 �C

PE

PE has good resistance to abrasion, chemical agents and caustic solutions. However, its friction coefficient is low. Suitable for food applications. Temp: -40 +80 ºC.

These gaskets can be manufactured in compliance with Standards DIN 2690, DIN 2691 and B 16.21 for raised-face and flat-face flanges. We have a large stock of standard gaskets for immediate delivery.

For further information about materials and sizes see the Download section

GENERAL CHARACTERISTICS OF RUBBER GASKETS

There is a wide range of rubber materials that can be used for sealing. Rubber gaskets are generally the best type of seal for use in low-medium temperature and low pressure environments.

SBR

SBR offers excellent resistance to abrasion and is recommended for working with weak acids and water. It is not recommended for use with ozone, hydrocarbons and hard acids. Temp: -25 +70 ºC.

Neoprene

Neoprene offers excellent resistance to oils, low permeability to gases and excellent resistance to ozone, abrasion and bending. It is not recommended for use with hard acids, aromatic and oxygenated solvents. Temp: -35+105 ºC

NBR

NBR is a synthetic rubber with excellent resistance to hydraulic fluids, oils, lubricants, petroleum, transmission fluids and solvents. Temp: -35 +105 ºC.

EPDM

EPDM offers good resistance to ozone, heat, steam, hard acids and alkalis. It is not recommended for use with oils, solvents and aromatic hydrocarbons. Temp: 15 +130 ºC.

Viton

Viton offers excellent resistance to chemical attack, acids, oils, petroleum and corrosive environments. It has high thermal stability at high temperatures.

Silicona

Silicone is a rubber that has excellent properties at high and low temperatures. It has excellent resistance to compression, sunlight, ozone and oxygen. It is suitable for use with food products. Temp: -40 +200 ºC.

These gaskets can be manufactured in compliance with Standards DIN 2690, DIN 2691 and B 16.21 for raised-face and flat-face flanges. We have a large stock of standard gaskets and o-rings for immediate delivery.

For further information about materials and sizes see the Download section

GENERAL CHARACTERISTICS OF GRAPHITE GASKETS

Expanded graphite is one of the best asbestos-free alternatives to seals for gases and fluids. It is a high performance sealing material at high and low temperatures, even in contact with extremely corrosive chemical agents. It retains all of its properties at high temperatures of up to 450 ºC and is particularly resistant to changes in temperature. The stainless steel in the sheeting increases its mechanical resistance and service pressure, in addition to making it easier to handle.

Qualities

- Expanded graphite

- Expanded graphite with 316 plain 0.05 mm stainless steel

- Expanded graphite with 316 perforated 0.1 mm stainless steel

These gaskets can be manufactured in compliance with Standards DIN 2690, DIN 2691 and B 16.21 for raised-face and flat-face flanges. We have a large stock of standard gaskets for immediate delivery.

For further information about materials and sizes see the Download section

Datasheets

SPIRAL WOUND GASKETS

These spiral shaped gaskets are made up of a metal strip with a V profile and a soft filler material such as compressed cardboard, graphite, ceramic fibre, fibreglass, PTFE, etc. The soft material acts as the sealing element by not allowing fluids to leak, whilst the metal strip provides structural properties. They are usually round, oval, rectangular, pear-shaped or diamond-shaped.

For further information about materials and sizes see the Download section.

JACKETED GASKETS

These gaskets are made of a soft material (graphite, PTFE, compressed cardboard, etc.) surrounded by metal (stainless steel, copper, nickel, brass, monel, silver, titanium, etc.), which covers both the inner and outer diameters, and the two contact surfaces. If the materials are properly selected, jacketed gaskets are able to withstand high temperatures and pressures, and they are even able to withstand compression of 20–30% of their original thickness. They are usually round, rectangular or oval. They are commonly used in heat exchange equipment.

For further information about materials and sizes see the Download section